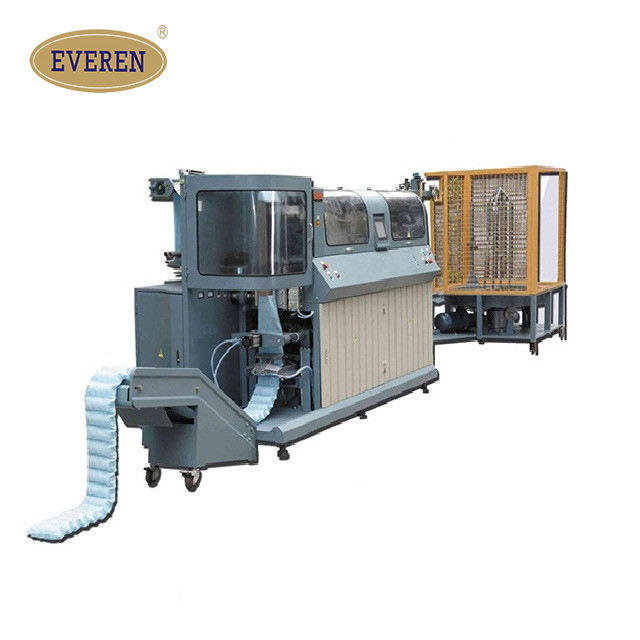

Feature:

- High cost effectiveness

- High Stability , Low malfunction rate , Low rejection rate

- CE-Conform ,International standard components

- Elective bottom seal or dorsal seal

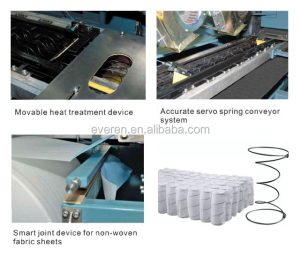

- Compact design /Electro- mechanical conveyor are controlled by servo/accurate motions

- Intelligent sensors can check malfunctions all the time / Display corresponding alarm on the HIM duly / one operator can run several sets of LR-PS-HF alone

- Unique patented spring conveyor design increases productivity and efficiency

- Very operator user-friendly non-woven joint device / save time and non-woven

- Automatic cutter for the pocket springs can be selected as an additional part

- Ultrasonic horn is made of Titanium /Durable and Firm’

- Low and easy maintenance

- Easy to operate / short training period

- Spare parts are “off the shelf ”

Technical parameter:

General Data:

| Model | EE-PS-HF |

| Production Capacity | 70 springs/minute |

| Coiling head | One cam coiling head |

| Working principle | Servo control |

| Spring shape | Barrel and cylindrical |

| Air Consumption | 0. 5m³/min |

| Air pressure | 0.6-0.7mpa |

| Power consumption in total | 21kw |

| Voltage | 3AC 380V |

| Frequency | 50/60HZ |

| Input current | 32A |

| Cable section | 4*10mm²+1*6mm² |

| Working temperature | +5℃ to- + 35 ℃ |

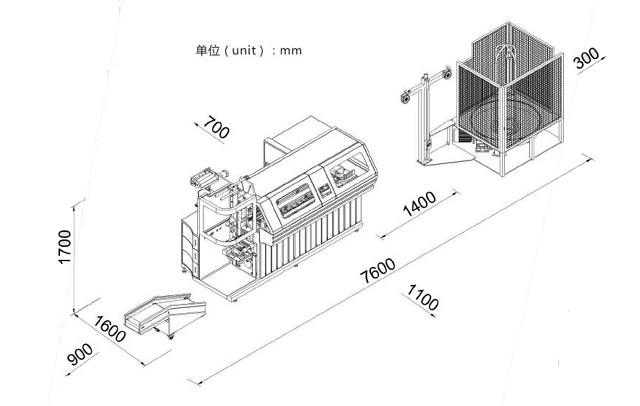

| Weight | Approx.3200kgs |

Consumption Material Data:

| Non-woven fabric data | Steel Wire | ||

| Fabric density | 65-90g/m² | Wire Diameter | 1.6-2.3mm |

| Fabric width | 220-600mm |

Inner dia.of wire roll |

Min.320mm |

|

Inner dia.of fabric roll |

Min.60mm |

Outer dia.of wire roll | Max.1000mm |

| Outer dia.of fabric roll | Max.600mm | Acceptable weight of wire roll | Max.800kg |

Working Range:

| Option | Wire Diameter (mm) | Spring Waist Diameter(mm) | Pocket Spring Height(mm) | |

|

Standard |

Option-01 | 1.6-2.2 | 55-75 | 80-220 |

| Option-02 | 1.6-2.3 | 65-80 | 120-300 | |

| Option-03 | 1.0-1.6 | 37-50 |

100-200 |